by Olha Romaniuk

In 2012 the Port Authority decided that one way of addressing this issue was to generate new approaches to the problem by staging a competition. Thus, the Next Generation Container Port (NGCP) Challenge was born. Its main thrust focused on gathering ideas and concepts in planning, design and operations, which could be applied to its container port. The deliberate decision, to keep the location of the site as somewhat generic, aimed for proposals and concepts that could be implemented at any port in the world. “We believe that this competition will allow us to identify ideas that will not only benefit the port of Singapore, but also revolutionize the entire container port industry,” said Captain M. Segar, MPA’s Assistant Chief Executive.

The initial competition brief heavily emphasized three concepts above the rest, guiding the competition entrants toward efficient, performance-oriented and environmentally sustainable design. Technical requirements included specifications for a next-generation container port that would be functional ten years from the announcement of the competition, with operational specifications including at least 80% transhipment cargo capacity, round-the-clock operations, and a 4-day-average container dwell time. Sustainability measures had to take into an account environmental as well as financial considerations. Key design aspects included loading/unloading requirements, storage and retrieval, labor productivity, land use and environmental protection.

The official registration for the competition began in April 2012 with the release of the detailed problem statement and competition document. A lucrative prize of US$1 million and up to 6 commendation prizes, each consisting of US$100,000, were revealed as compensation awards to the deserving runner-up teams.

The designations and posts held by the members of the judging panel clearly indicated a preference for technical and research-supposed submissions over conceptual designs. Technical restrictions and specifications, including a mandatory computation of key performance factors, led to a large number of submissions (approximately 85% according to the Maritime and Port Authority) to come from highly specialized university-based research teams and engineering consultants. While the organizers of the competition made no concrete promises for in-depth development of the winning design, they had vowed to set aside up to S$5 million for further research and implementation of worthy solutions arising from the competition.

The Finalists

While the list of initial registrants included a lengthy roster of architectural firms and schools, collaborations with research institutions and engineering and consulting agencies proved to be the most fruitful, as the competition objectives implicitly called for expertise and experience within the maritime industry. From a total of 56 submissions from 25 countries, 7 finalists were selected based on a technical evaluation of the performance, productivity and sustainability of their proposals. Those finalists were:

- Cogent Holdings Limited – AC Consortium Pte Ltd – Engineers Partnership LLP – E S Tang Consultants, Singapore

- National Sun Yat-Sen University – Port of Kaohsiung, Taiwan International Ports Co,. LTD – Taiwan International Ports Co,. LTD – LUP International Co., LTD – National Taiwan Ocean University – 3fp Landscape Atelier Pte Ltd – Chi Architects & Associate

- Jurong Consultants – KH Leong Consultancy Services

- National University of Singapore – Shanghai Maritime University – Shanghai Zhenhua Heavy Industries Company Limited

- Moffatt & Nichol – National University of Singapore – NDI Automation – Yagertec System Solutions (S) Pte Ltd

- Nanyang Technological University – APL Co Ltd – Fraunhofer IDM@NTU – Kalmar – VTT Technical Research Centre of Finland

- Nanyang Technological University

On April 5th, 2013, the shortlisted finalists were invited to make presentations before the international panel of judges, including representatives from the maritime industry and from the Singapore government. A joint statement from MPA and SMI disclosed, “The seven shortlisted proposals were clearly detailed and were supported with technical analysis and simulation studies to illustrate their designs and operating concepts. The selection committee also honored finalists with teams made up of entities from the tertiary and research institutes, port consultancy firms and engineering and design firms, which allowed them to submit comprehensive proposals.” Less than 15% of entries were strictly conceptual designs.

Teams focused heavily on automation as a means of achieving efficiency and the now-standard answer to renewable energy in a form of solar panels. Cogent Holdings Limited, for example, estimated that solar panels would be able to supply 11% of their port proposal’s energy needs. US-based Moffatt & Nochol and the National University of Singapore embraced automation that would do the job faster over longer horizontal distances.

While there are no immediate plans to implement the winning port design in its entirety, there is a huge potential for the winning ideas to materialize in Singapore when the city-state completes the development of the Tuas Port, where all of Singapore’s container port activities will be subsequently relocated. According to MPA and SMI, “The organizers will work with terminal operators in Singapore to identify design components in the proposals that are worthwhile for further research and test bedding. Depending on the outcome of these R&D activities, particular concepts or technologies could be considered for the planning of future new container terminals.”

The Winner

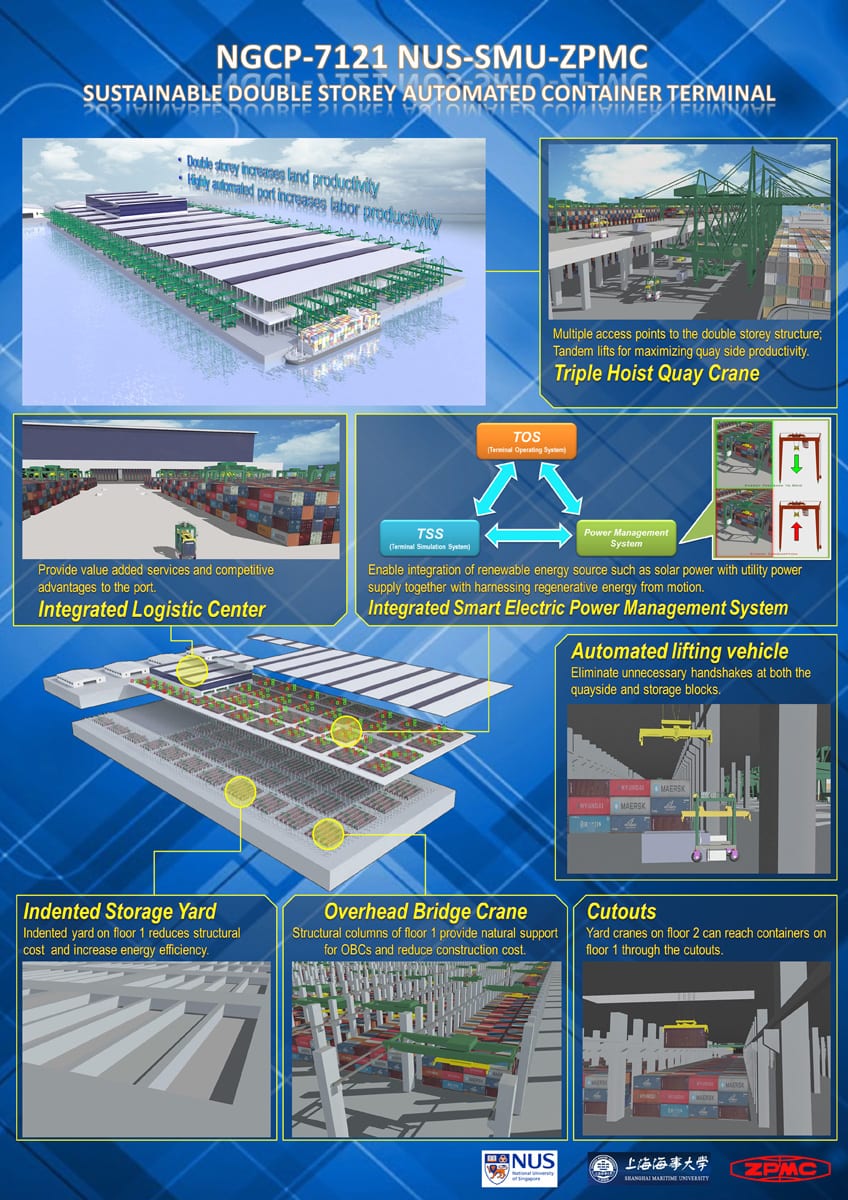

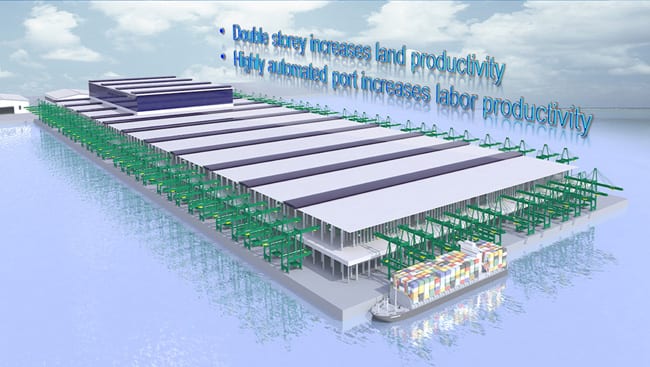

National University of Singapore – Shanghai Maritime University – Shanghai Zhenhua Heavy Industries Company Limited

The winning proposal, “SINGA Port,” that took the US$1 million first prize, was a collaboration between team members from the National University of Singapore, Shanghai Maritime University and Shanghai Zhenhua Heavy Industries Company Limited. A playful acronym of the port concept, Sustainable Integrated Next Generation Advanced, or “SINGA Port” for short, broke away from the standard “flat” shipyard with an introduction of a double-story stacking configuration, allowing shipyards to store double the amount of containers and shorten the transportation time. An unusual feature of the double-storey design is that it allows for part of the storage to occur below ground by digging a trench to store three boxes. The structural height is thus reduced because the second level is at a lower level than normal. This can reduce construction costs by as much as thirty percent by cutting the height of stacking by half.

Thus, by placing high emphasis on efficiency, the team was able to occupy 80% of the 1-kilometer by 2.5-kilometer area with the required amount of cargo and designate the rest of the space to accommodate a logistics center on site. Sustainability considerations included the implementation of the electricity-powered automatic lifting vehicles, noticeably reducing the pollution levels typically generated by a comparable container port.

The proposal’s main design objectives catered closely to the land-scarce Singapore, where the lack of space has consistently been one of the most persistent problems in the recent history. Utilitarian, but one of the most efficient of all proposals, the design stood out as a winner among the judging panel members, most of whom were very familiar with maritime operations.*

Runner-up

Cogent Holdings Limited – AC Consortium Pte Ltd – Engineers Partnership LLP – E S Tang Consultants

Other proposals exhibited similar aspirations of balancing efficiency with sustainability and performance optimization strategies. This proposal by Cogent Holdings Limited integrated a container port yard, characterized by modular storage units and electricity generating cranes, with the operations and supporting services within the given 2.5-kilometer site. The layout of the container storage yard relied on a slabless design structure to provide more storage capacity, while the solar panels on top of each modular structure provided a standard solution for a more self-sustaining container port.

While the comprehensive and orderly layout of the site dictated the aesthetics of the port, the design team created a friendlier and more visually appealing front façade and entry area that marked a departure from the more industrial guts of the port itself. A green living wall and trellises were used to break up the monotonous solidity of the front façade with vertical slivers of color, while the welcoming landscape at the entry point of the port integrated its presence within the surrounding context.

Runner-up

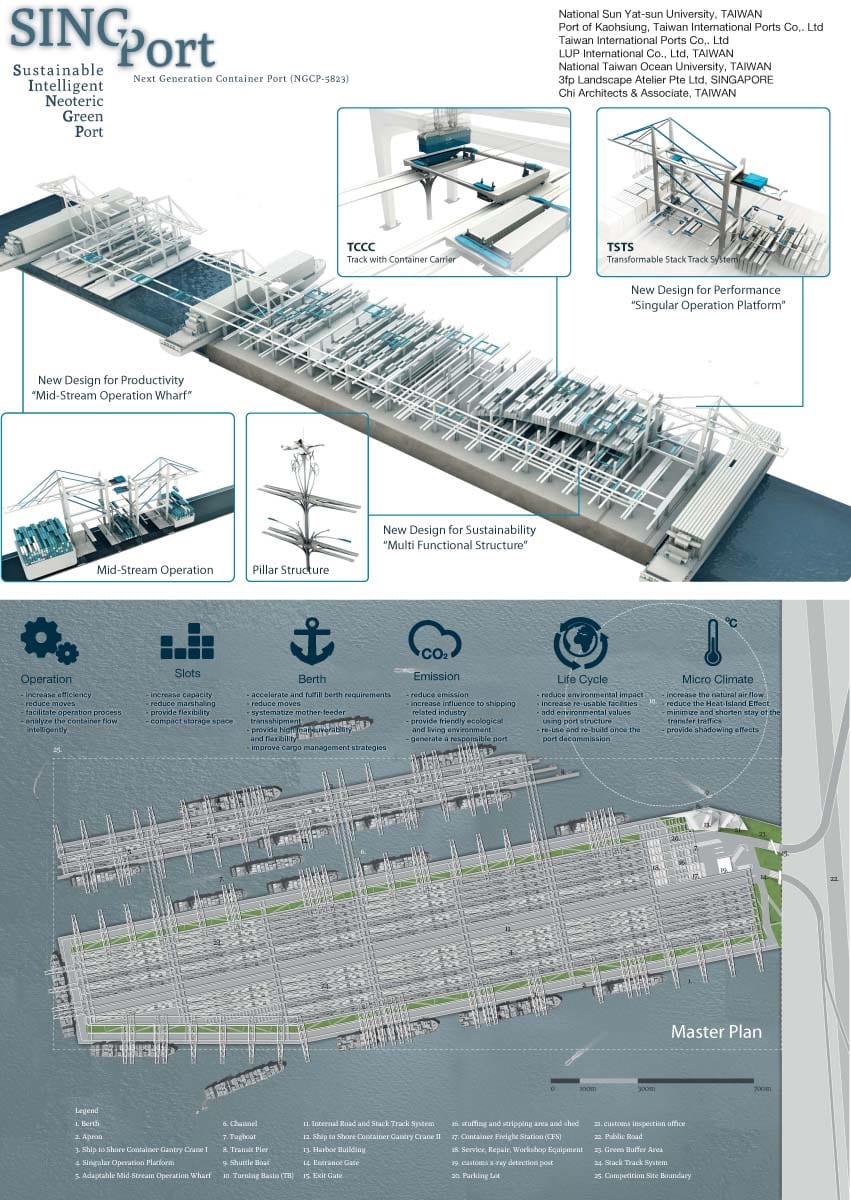

National Sun Yat-Sen University – Port of Kaohsiung, Taiwan International Ports Co,. LTD – Taiwan International Ports Co,. LTD – LUP International Co., LTD – National Taiwan Ocean University – 3fp Landscape Atelier Pte Ltd – Chi Architects & Associate

An interesting proposal by the National Sun Yat-Sen University and its team of collaborators showed a design that, while addressing the productivity and operational challenges of a container port, also placed a high emphasis of multi-functionality of the proposed structures and innovative sustainable solutions to reduce the environmental impact and the CO2 emissions of the port. The multifunctional pillar structure within the orderly layout of the containers showcased an ingenious solution to integrating sustainable design features and lighting within a structural column. The design team also made some assumptions about the location of the site, in order to plan a layout of storage and operations facilities to create a more environmentally conscious port design. The team laid out the site plan in such a way as to increase the natural airflow and reduce the Heat-Island Effect, while providing shading that is much needed in the tropical climates. The green buffer area at the entry and around the perimeter of the port was created to conceal the port’s facilities from the surrounding context and provide a friendlier façade.

Emission reduction was another consideration within this port design. The design team analyzed the typical flow of containers, from the time they arrive in the port. The findings allowed for an intelligent layout to reduce the unnecessary moves within the facilities and a shorter duration of stay of the transfer traffic.

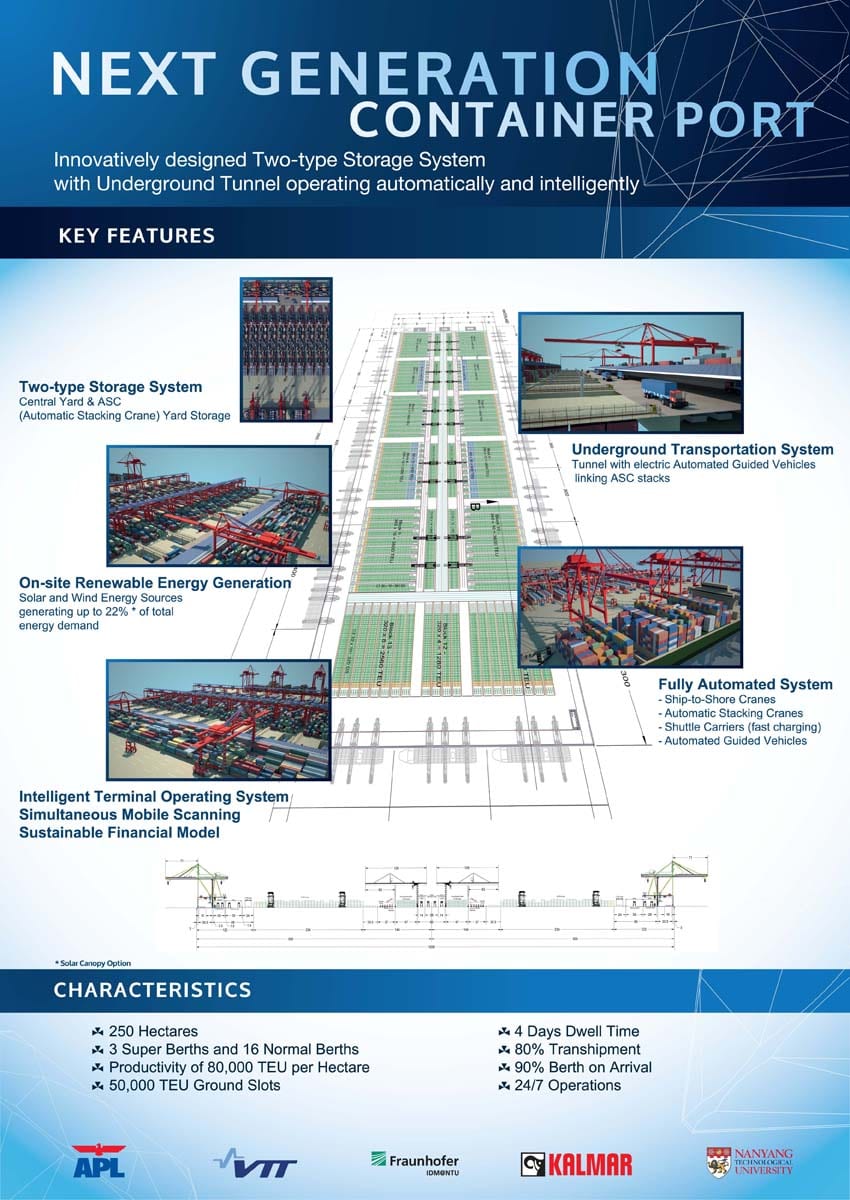

Nanyang Technological University – APL Co Ltd – Fraunhofer IDM@NTU – Kalmar – VTT Technical Research Centre of Finland

A team comprised of the Nanyang Technological University, APL Co Ltd, Fraunhofer IDM@NTU, Kalmar and VTT Technical Research Centre of Finland focused on efficiency and minimizing the structural presence at the ground level of the proposed container port design. Going subterranean allowed the team to avoid building columns at the ground level and facilitate an easier free flow of containers around the port.

Finalists

Jurong Consultants – KH Leong Consultancy Services:

Moffatt & Nichol – National University of Singapore – NDI Automation – Yagertec System Solutions (S) Pte Ltd:

Nanyang Technological University:

Olha Romaniuk is an architectural and exhibit designer at Gallagher and Associates Asia and an alumna of the University of Cincinnati’s Master of Architecture program. She currently resides in Singapore, where she designs museum interiors, exhibits and installations and regularly contributes to various local and international architectural publications.